Ultrasonic Welding Machine for Textile – Seamless, Fast, and Eco-Friendly Fabric Bonding

Introduction

The textile industry is evolving rapidly, demanding cleaner, faster, and more efficient production methods. The Ultrasonic Welding Machine for Textile is a revolutionary solution that enables stitch-free, chemical-free, and high-speed fabric bonding. Using high-frequency vibrations, this machine fuses synthetic and nonwoven fabrics with precision and strength, offering superior alternatives to traditional sewing and adhesive methods.

Whether used for medical gowns, nonwoven masks, filter bags, or lace trims, ultrasonic textile welding delivers beautiful, durable, and hygienic seams without needles or thread.

What Is an Ultrasonic Textile Welding Machine?

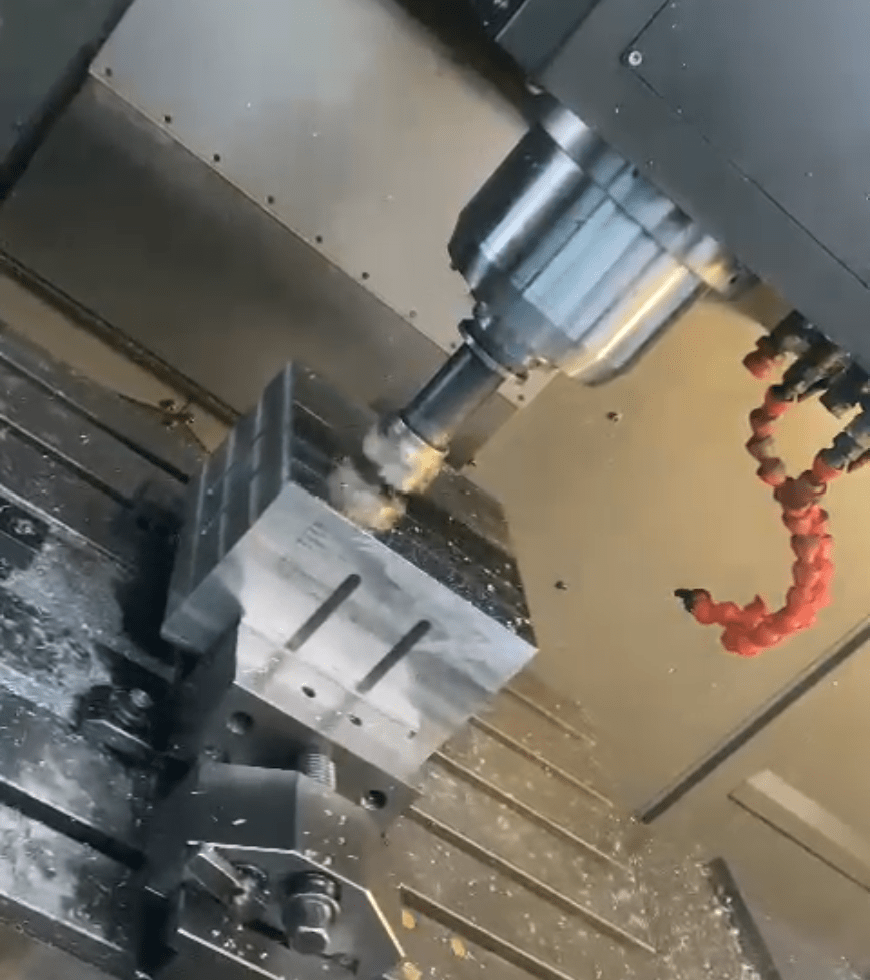

An ultrasonic welding machine for textile uses 20–35 kHz high-frequency sound waves to generate localized heat at the contact point between synthetic or thermoplastic fabrics. The heat softens the material, and with controlled pressure, bonds the layers together, creating a strong, clean seam or patterned edge.

How It Works:

- Fabric layers are fed through a rotating patterned anvil.

- A vibrating ultrasonic horn applies pressure.

- The materials fuse under vibration and pressure.

- The welded fabric exits sealed, cut, or embossed, depending on the die used.

Key Features

- No Stitching or Thread Required

- Silent and Vibration-Free Operation

- Clean Edge Sealing and Cutting

- Compatible with Thermoplastic and Nonwoven Materials

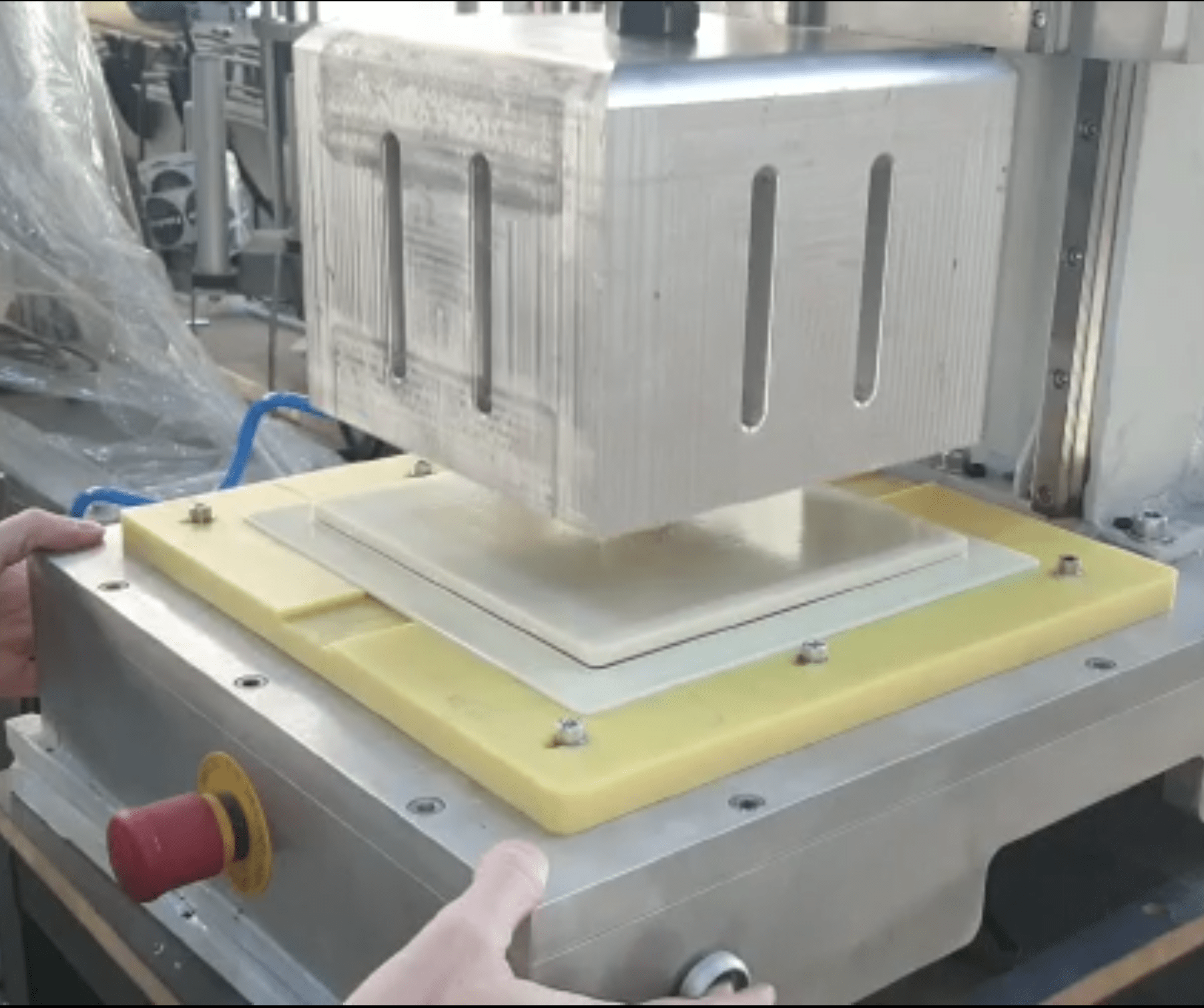

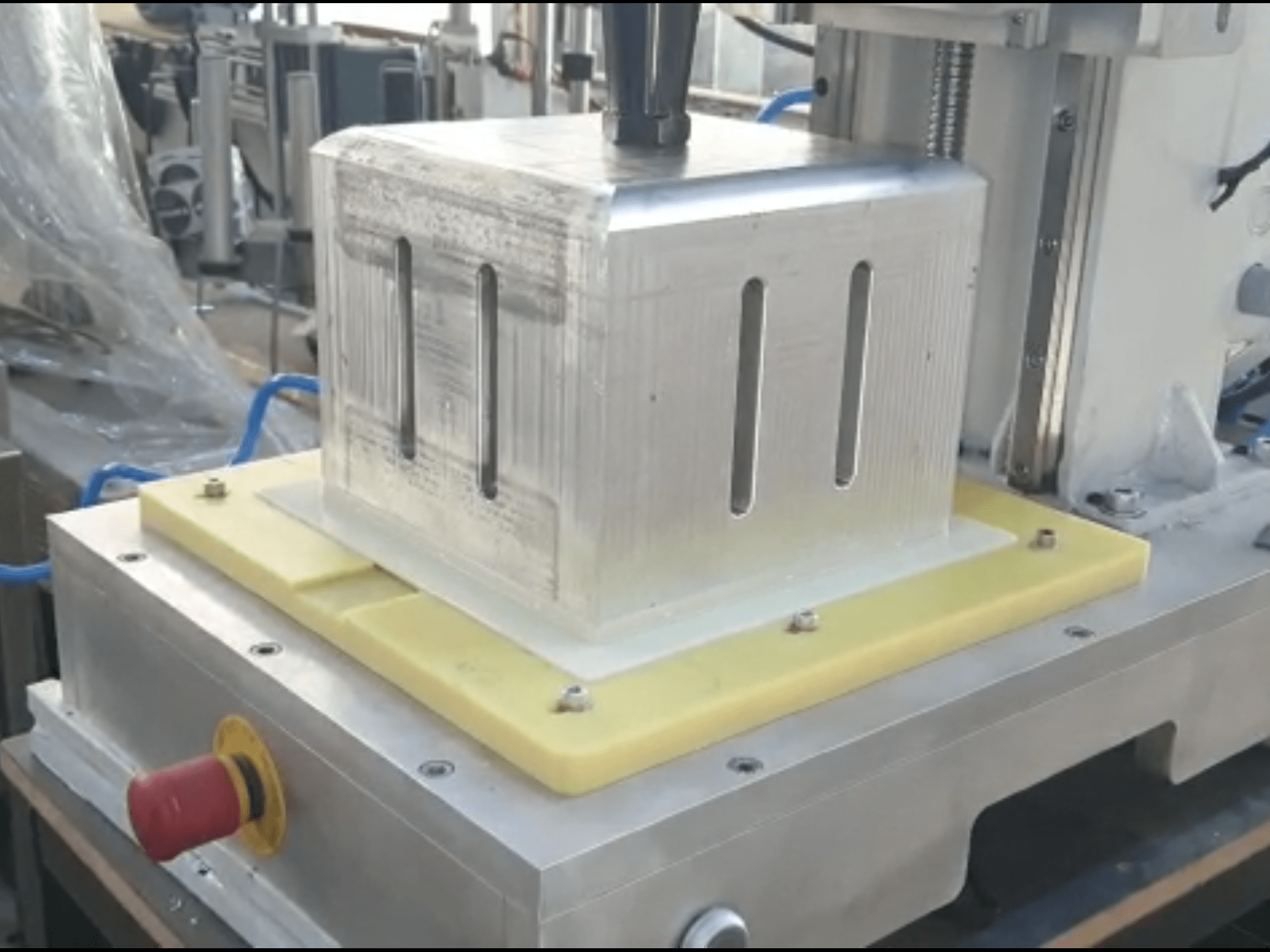

- Rotary Anvil for Decorative and Functional Patterns

- Single or Multi-Layer Welding

- Compact Design – Tabletop or Industrial Models Available

Benefits of Ultrasonic Welding in Textiles

1. Speed and Efficiency

Ultrasonic welding is significantly faster than traditional sewing or gluing methods, making it ideal for mass production in medical, hygiene, and apparel industries.

2. Hygienic and Seamless

The process produces sealed edges without holes, reducing contamination and enhancing hygiene — perfect for disposable medical garments, masks, and food-safe fabrics.

3. Cost-Effective

Since there’s no need for thread, adhesives, or drying time, production becomes more streamlined and cost-effective.

4. Flexible Design Options

The rotary die allows decorative embossing, trimming, spot welding, and cutting, all in one pass.

Common Applications

- Surgical gowns and drapes

- Face masks (N95, surgical, etc.)

- Sanitary napkins and diapers

- Filters (air, water, vacuum)

- Bra cups, corsets, and lingerie

- Decorative lace and curtains

- Shopping bags and packaging materials

Technical Specifications

| Feature | Specification |

|---|---|

| Ultrasonic Frequency | 20 kHz / 35 kHz |

| Power Output | 1000W – 3000W |

| Welding Width | 10mm – 60mm (customizable) |

| Speed | Up to 20 meters per minute |

| Welding Pattern | Standard and custom rotary dies |

| Material Compatibility | Polyester, Nylon, PP, Nonwoven, PE blends |

| Machine Type | Standalone, handheld, or inline integration |

Why Choose Our Ultrasonic Textile Welding Machines?

Our ultrasonic textile welders are engineered for precision, durability, and versatility. From high-speed industrial lines to compact manual models, we provide the right solution for any textile bonding application. Our machines are CE-certified, robustly constructed, and supported by a team of ultrasonic technology experts.

Highlights:

- Custom rotary embossing wheels available

- Adjustable welding pressure, amplitude, and speed

- Easy-to-use touch control interface

- Low maintenance, long service life

- Optional auto fabric feeders and tension controllers

- Training and global technical support